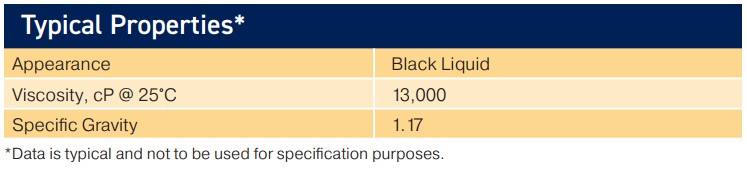

NameLORD Thermoset EP-20 Epoxy Resin

ThermosetTM EP-20 epoxy resin is a general purpose, unfilled epoxy resin formulated for use with several Thermoset hardeners to obtain a variety of handling and cured properties. Thermoset EP-20 epoxy resin can be used in many applications including adhesive, laminating and electrical/electronic insulation.

Features and Benefits:

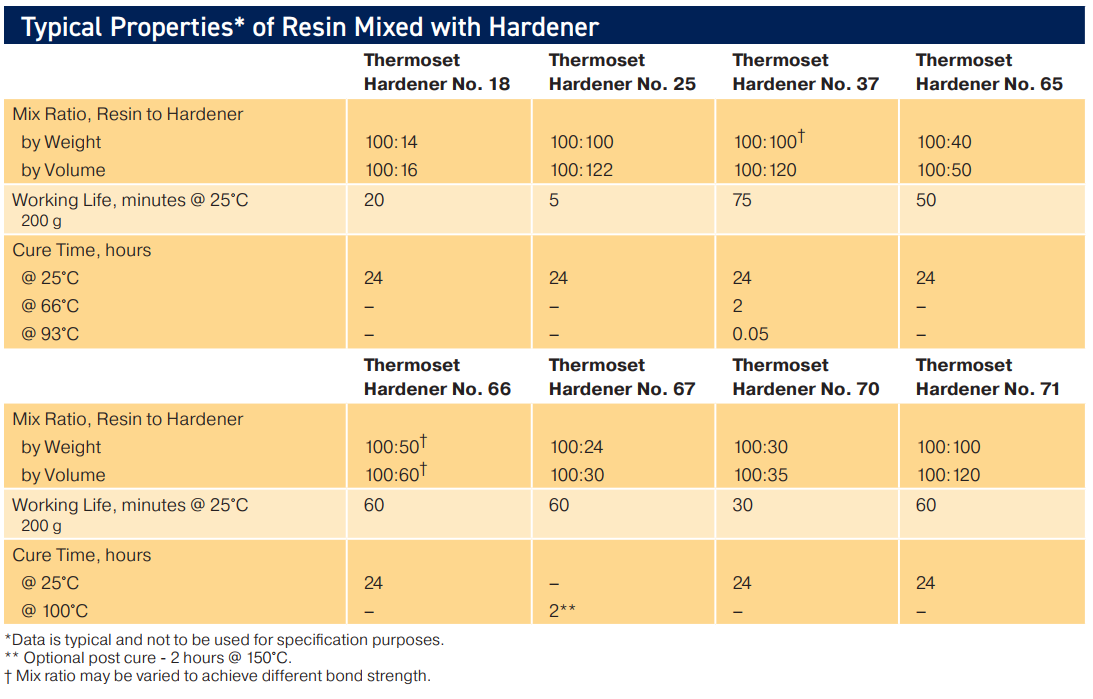

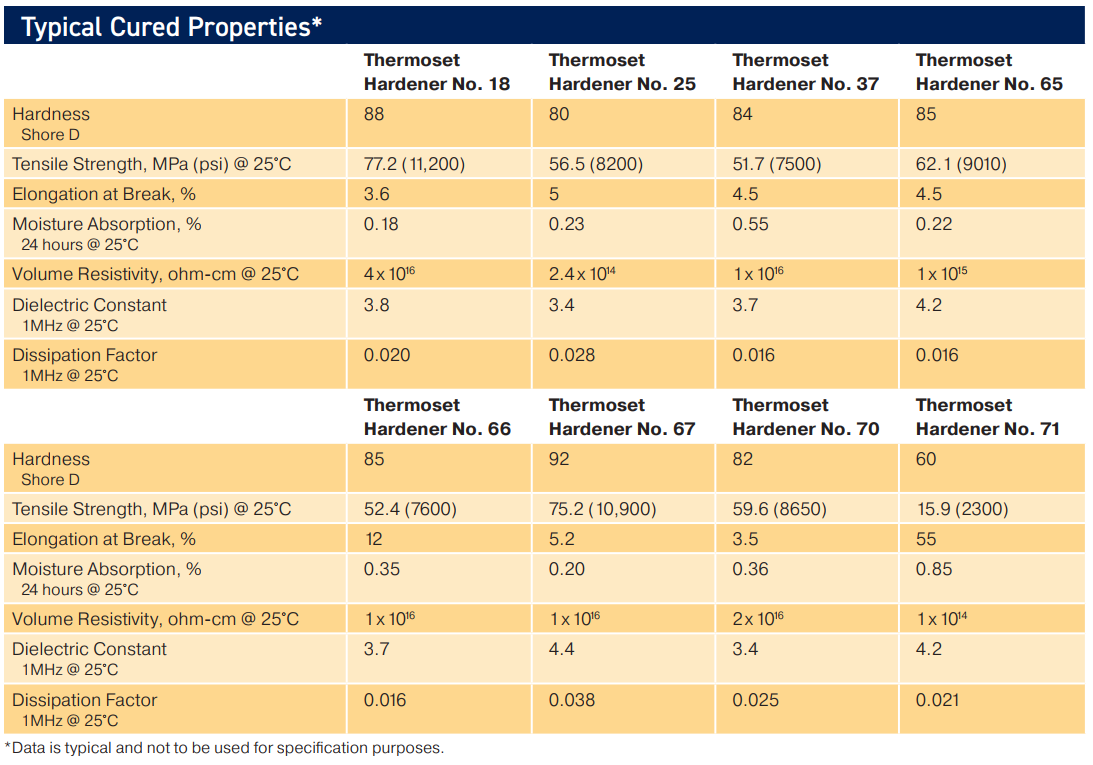

Handling and cured properties of the two-component epoxy system are dependent on the hardener used with Thermoset EP-20 epoxy resin.

Thermoset Hardener No. 18

• Low Viscosity – maintains low viscosity for complete and void-free encapsulation.

• Heat Resistant – provides superior heat resistance for room-temperature cured system.

Thermoset Hardener No. 25

• Excellent Appearance – cures to a high gloss surface, free of “sweat-out”; exhibits good mar resistance.

• Fast Cure – rapidly cures at room temperature (25°C).

• Moisture Insensitive – cured properties obtained even when cured in high humidity conditions.

Thermoset Hardener No. 37

• Flexible Bond Strength – provides high bond strength for use as an adhesive to a variety of surfaces. Rigidity of bond may be varied depending on mix ratio.

A 1:2 (resin to hardener, by weight) ratio will yield a relatively flexible bond; a 3:2 ratio will provide a rigid bond.

Thermoset Hardener No. 65

• Low Viscosity – maintains low viscosity for complete and void-free encapsulation.

• Excellent Appearance – cures to a high gloss surface, free of “blush” or “sweat-out”.

Thermoset Hardener No. 66

• Flexible Bond Strength – provides high bond strength for use as an adhesive to a variety of surfaces. Rigidity of bond may be varied depending on mix ratio.

A 1:2 (resin to hardener, by weight) ratio will yield a relatively flexible bond; a 2:1 ratio will provide a rigid bond.

• Convenient – provides a working life of over one hour; cures at room temperature or with mild elevated temperature.

Thermoset Hardener No. 67

• Elevated Temperature Cure – requires an elevated temperature cure to obtain a rigid bond.

• High Temperature Resistant – provides good resistance for cured system that experiences continuous operating temperature up to 155°C.

• Chemically Resistant – cured system provides excellent resistance to chemicals.

Thermoset Hardener No. 70

• Low Viscosity – maintains low viscosity for complete and void-free encapsulation.

• Environmentally Resistant – cured system provides high impact strength and thermal shock resistance.

Thermoset Hardener No. 71

• Low Exotherm – exhibits low exothermic heat rise during room temperature cure.

• Environmentally Resistant – cured system provides excellent mechanical and thermal shock resistance; retains flexibility even after severe heat aging.

Application:

Mixing – Transfer amount of resin needed to a clean container and add proper amount of hardener by weight. Thoroughly mix resin and hardener together. Automatic meter/mix/dispense equipment may be used for high volume production. Unless a closed-chamber mechanical mixer is used, air may be introduced when catalyzing the mixture. Electrical properties of the epoxy are best when air bubbles and voids are minimized. Therefore, in extremely high voltage or other critical applications, vacuuming may be appropriate.

Applying – Apply epoxy system using automatic meter/mix/dispense equipment.

Curing – Cure time will vary depending on hardener used. Refer to cure schedule indicated below. This time-attemperature profile refers to the time the material should be allowed to cure once it reaches the target temperature. Allowance should be made for oven ramp rates, parts with large thermal mass and other circumstances that may delay material reaching the target temperature.

Cleanup – Disposable containers and utensils are recommended when working with epoxies. However, when disposable materials are impractical, uncured epoxy can be removed by cleaning equipment with solvent. Solventcleaned utensils should be thoroughly dried before reuse; any remaining solvent can contaminate the next mixture.

Shelf Life/Storage:

Shelf life is two years when stored at 25°C in original, unopened container. The material container must be periodically rotated to prevent settling.

Copyright @ Shanghai Mingfen Electronic Technology Co., Ltd 沪ICP备12022625号-1 Technical support: 300.CN Shanghai