NameLORD CoolTherm® UR-389 Flame Retardant Urethane Encapsulant

CoolTherm® UR-389 encapsulant is a two-component urethane system designed for encapsulating and casting applications.

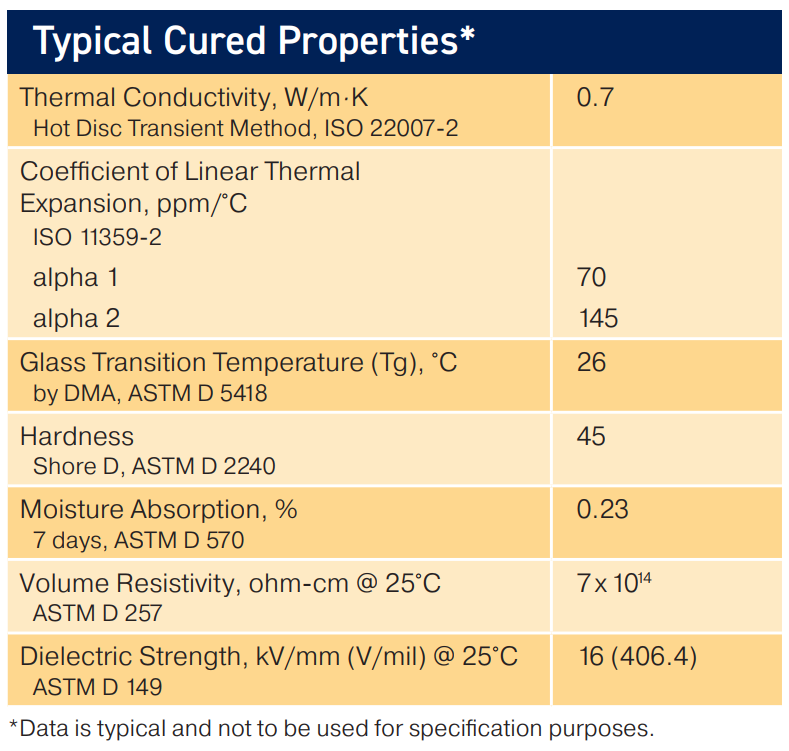

CoolTherm UR-389 encapsulant cures at room temperature to produce a flame retardant, semiflexible material.

Features and Benefits:

Low Stress – exhibits low shrinkage and stress on components as it cures.

Low Viscosity – maintains low viscosity for complete and void-free encapsulation.

Room Temperature Cure – suitable for curing at room temperature; may be mildly heat cured (65°C) to expedite cure.

Environmentally Resistant – provides excellent thermal shock resistance.

UL Rated – provides excellent flame retardancy; UL 94 V-0 certified.

Application:

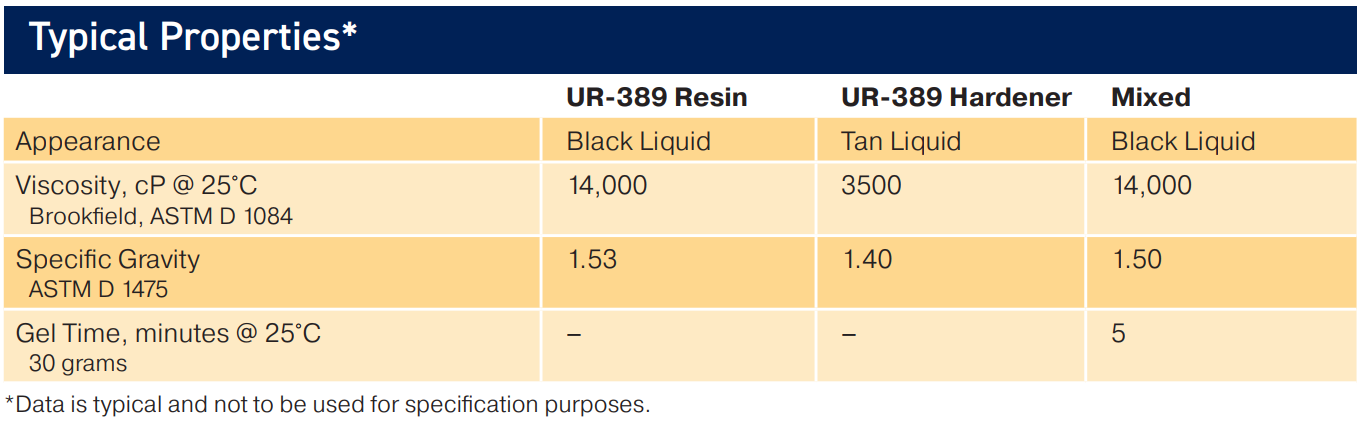

Mixing – Thoroughly mix each component prior to combining resin and hardener. Mix CoolTherm UR-389 resin with CoolTherm UR-389 hardener at a 100:25 ratio, by volume (100:23, by weight). Automatic meter/mix/dispense equipment may be used for high volume production. Use at least 24-element mix tips to ensure proper mixing of the encapsulant.

Applying – Apply encapsulant using handheld cartridges or automatic meter/mix/dispense equipment.

Curing – Encapsulant will initially cure in less than 60 minutes at 25°C. Suggested cure schedule is 24 hours at 25°C, or 2 hours at 70°C. Larger potting volumes will cure at a faster rate.

Shelf Life/Storage:

Shelf life of each component is six months when stored in a clean, dry environment at 18-30°C in original, unopened container. CoolTherm UR-389 resin and hardener containers must be periodically inverted to prevent settling. After opening, protect each component from excessive moisture by using dry nitrogen as an inert cover. If stored or shipped at cooler temperatures, CoolTherm UR-389 hardener may crystallize. If crystals appear, gently warm hardener at 30-50°C to melt crystals before mixing with resin. Limit heating period to less than three hours as excessive heating will cause dimerization.

Copyright @ Shanghai Mingfen Electronic Technology Co., Ltd 沪ICP备12022625号-1 Technical support: 300.CN Shanghai