NameESP8660-FP

10 Micron or Thinner BLT

High Moisture Resistance

Electrically Conductive

Epoxy Film Adhesive

IDEALFOR:

High Volume, Automated Assemblies

High Power Processors and Devices

Wafer Level Die-attach

10 Micron Thickness

DESCRIPIION:

WL-ESP8660-FP is a die attach film(DAF)with for high power lowbondline thickness of 10 micron or less application. It is a micro-silverfilled high-bond strength epoxy film adhesive that can be used to laminateonto wafer and transfer to dicing tape for dicing.

It is designed for wafer level die attach application. WL-ESP8660-FP hasgood thermal stability. The dry, tack-free handling of the film makes itsuitable for an automated assembly. It has been tested to be compatibleith chosen dicing tape laminated at ambient to be following with dicinginto singulated chips for die-bonding.

AVALABILY:

WL-ESP8660-FP is available in sheet or pre-cut wafer size and repeatpattern on a release liner carrier. Standard thickness of WL-ESP8660-FPis 10 microns on 75 micron release liner Thinner thickness on specialrequest.

APPLICATION PROCEDURES

(1)Keep product in protective bag when not in use.

(2)Before using. remove protective release liner from film. Place

(3)Laminate(low heat)wafer onto adhesive at 80+/-5C@ 10 psiDetailed processing time and pressure to be developed to ensureuniform wetting onto wafer. Cool to ambient before apply dicing tape.

(4)Laminate recommended dicing tape(consult ALT alse engineer)at ambient with nominal pressure to ensure intimate bonding withoutair bubble Perform dicing as usual.

(5)Die can be attached onto heated substrate above 125C and curewithout additional holding pressure.

Die Attach Film WL-ESP8660-FP

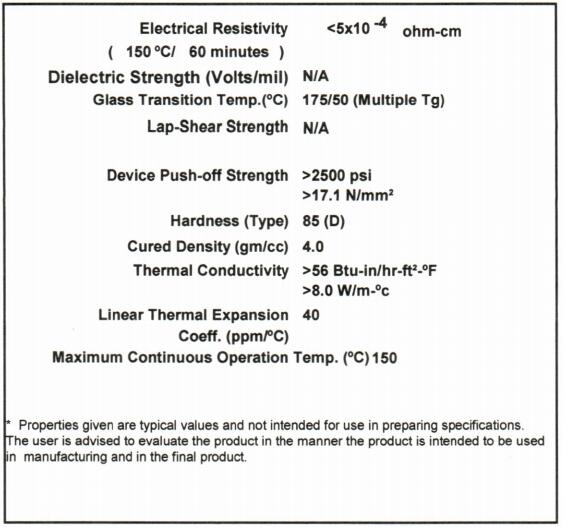

typical properties *

CURE SCHEDULESR

Temperature Time Pressure

125℃ 90min 8-15psi

150℃ 30min 8-15psi

For tack-and-cure: Tack the die with DAF with heated collet and heated stage holding the header, leadframe, module or substrate at 125-150oc Post curing at the same temperature

The die or component can also be tacked on the substrate at 80℃ or higher with 10 psi. When a fillet around the edge of the die or component is observed, the pressure can be released for the rest of the bonding cycleBesides major transition of Tg at around 175C, additional molecularrelaxation occurs at 50-120"C for stress absorption

SHELF LIFE:

Storage temperature Shelf Life

25℃ 1 yr in sealed package

Copyright @ Shanghai Mingfen Electronic Technology Co., Ltd 沪ICP备12022625号-1 Technical support: 300.CN Shanghai