NameLORD CoolTherm® SC-320 LVH Thermally Conductive Silicone Encapsulant

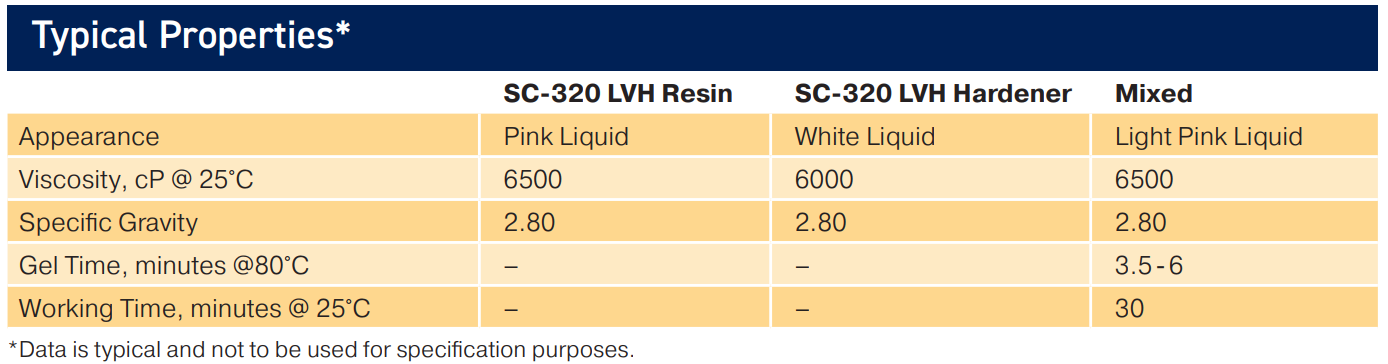

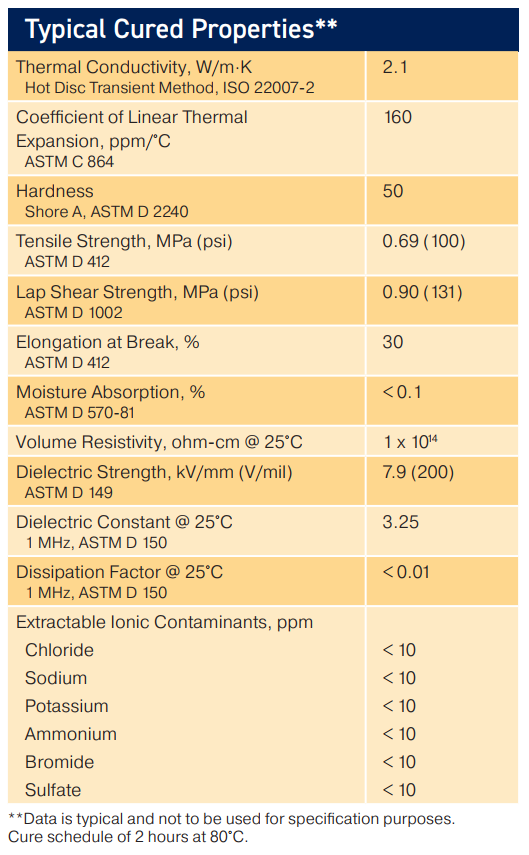

CoolTherm® SC-320 LVH (Low Viscosity) thermally conductive silicone encapsulant is a two-component system designed to provide excellent thermal conductivity for electrical/ electronic encapsulating applications, while retaining desirable properties associated with silicones.

Features and Benefits:

Low Viscosity – maintains low viscosity for ease of component encapsulation compared to other highly thermal conductive materials.

Low Stress – exhibits low shrinkage and stress on components as it cures.

Durable – composed of an addition-curing polymer that will not depolymerize when heated in confined spaces.

High Temperature Resistant – provides excellent resistance for cured system that experiences continuous operating temperature up to 200°C; provides excellent thermal shock resistance.

UL Rated – provides excellent flame retardancy; UL 94 V-0 certified.

Application:

Mixing – Thoroughly mix each component prior to combining resin and hardener. Mix CoolTherm SC-320 LVH resin with CoolTherm SC-320 LVH hardener at a 1:1 ratio, by weight or volume, until uniform in color. Automatic meter/mix/dispense equipment may be used for high volume production. Unless a closed-chamber mechanical mixer is used, air may be introduced into the encapsulant system either during mixing or when catalyzing the mixture. Electrical properties of the silicone encapsulant are best when air bubbles and voids are minimized. Therefore, in extremely high voltage or other critical applications, vacuuming may be appropriate.

Applying – Apply silicone encapsulant using handheld cartridges or automatic meter/mix/dispense equipment. Avoid applying encapsulant to surfaces that contain cure inhibiting ingredients, such as amines, sulfur, or tin salts. If bonding surface is in question, apply a test patch of encapsulant to the surface and allow it to set for the normal cure time.

Curing – Allow encapsulant to cure for 30 minutes at 80°C, or for 24 hours at room temperature (25°C). This time-at-temperature profile refers to the time the material should be allowed to cure once it reaches the target temperature. Allowance should be made for oven ramp rates, parts with large thermal mass and other circumstances that may delay material reaching the target temperature.

Shelf Life/Storage:

Shelf life of each component is nine months when stored at 25°C in original unopened container. CoolTherm SC-320 LVH encapsulant evolves minute quantities of hydrogen gas. Do not repackage or store material in unvented containers. Adequately ventilate work area to prevent the accumulation of gas.

Copyright @ Shanghai Mingfen Electronic Technology Co., Ltd 沪ICP备12022625号-1 Technical support: 300.CN Shanghai